ARE YOU SEEKING SURETY IN JUMPER BUOYANCY DESIGN, MANUFACTURE AND DELIVERY?

Established in 1980, Balmoral has an enviable reputation across the world for product design, development and delivery.

With 500+ people based at our purpose-built 250,000ft2 facility in Aberdeen, we build successful relationships with clients working with them from concept development and advice through to product design, manufacture, testing, delivery and support.

All managed in-house to give total safety, quality and scheduling control.

JUMPER BUOYANCY SOLUTIONS

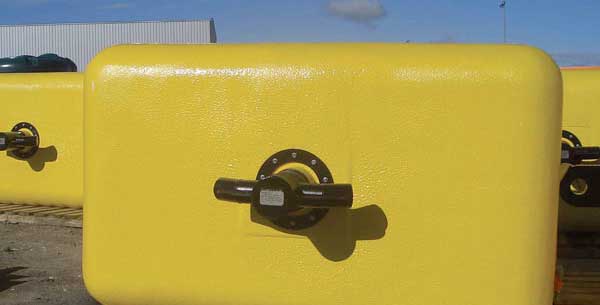

Balmoral Jumper buoyancy comprises two rotomoulded polyethylene half shells with integral clamping devices and is used to provide uplift on connecting sections of subsea pipe or flowlines.

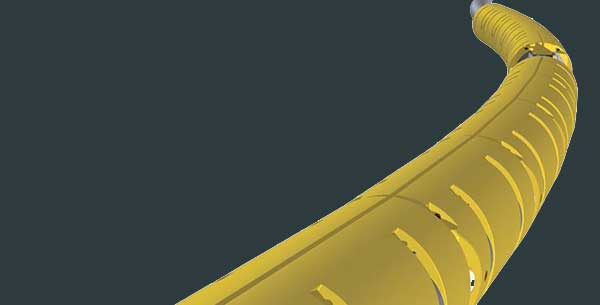

The modules can be produced with or without moulded helical strakes and are injected with high performance syntactic foams that are tailored to meet exacting performance, strength and installation requirements in water depths of 100-4000msw.

The modules are attached to the pipe or flowline using Balmoral’s patented integral clamping system.

Modules with moulded strakes are used where vortex induced vibration (VIV) challenges need to be addressed.