ARE YOU SEEKING SURETY IN BEND STIFFENER DESIGN, MANUFACTURE AND DELIVERY?

Established in 1980, Balmoral has an enviable reputation across the world for product design, development and delivery.

With 500+ people based at our purpose-built 250,000ft2 facility in Aberdeen, we build successful relationships with clients working with them from concept development and advice through to product design, manufacture, testing, delivery and support.

All managed in-house to give total safety, quality and scheduling control.

BEND STIFFENER SOLUTIONS

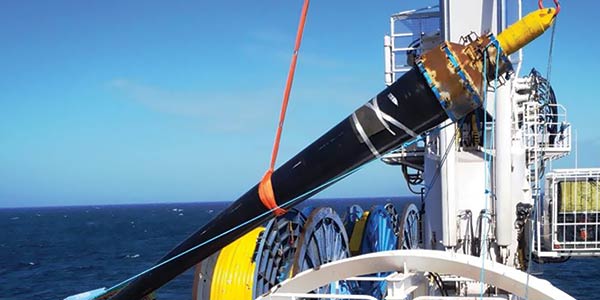

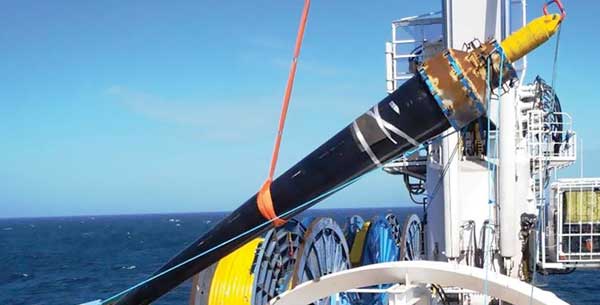

Bend stiffeners are used to support flexible pipe, umbilicals and cables when connected to rigid structures or a floating production system where there is a requirement to control the minimum bend radius of the pipe. They are usually attached at either the topside or seabed connection.

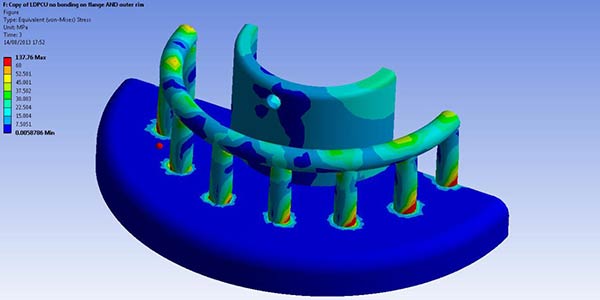

Balmoral bend stiffeners are fully accredited by Bureau Veritas to API 17L standards and, using specifically formulated polyurethane materials, are designed to suit engineered operational parameters including fluid temperature variance, project specific flowline, umbilical or cable stiffness and minimum bend radius (MBR) requirements.

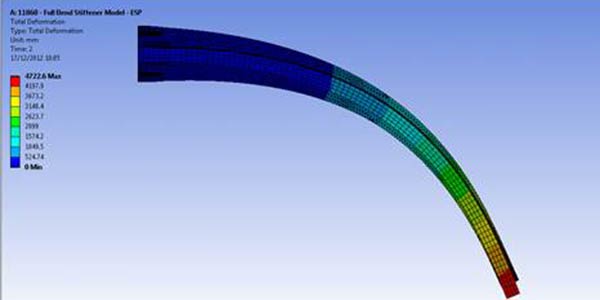

In dynamic applications bend stiffeners require to have sufficient fatigue resistance to control the in-service bend radii and sustain the cyclic loads to the end of the specified life whereas in static applications they protect against gross over-bending.

Stiffeners are typically conically shaped polyurethane mouldings with a cylindrical bore that slips over the pipe, umbilical or cable.

Advancing connections in offshore infrastructure

BEND STIFFENER

INNOVATIONS AND SOLUTIONS

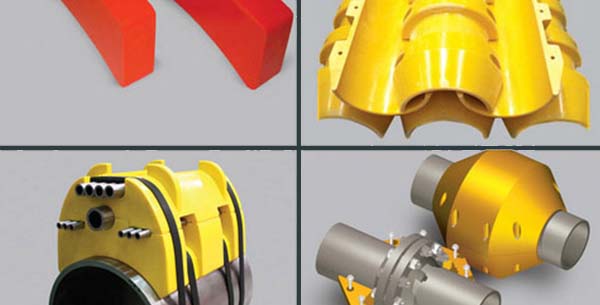

Balmoral boasts an unmatched reputation in clamping solutions for the distributed buoyancy market and has developed this capability for use in its bend stiffener range.

The DBM clamp design was altered by adding a funnel to provide load distribution along the body of the bend stiffener. This bridges over the vulnerable tip of the stiffener to prevent damage at this critical region of the stiffener.

This evolution was introduced following client requests and is used for two applications in particular:

- Pull in Allows fitting of the bend stiffener to the pipeline on deck prior to deployment. The clamp is installed a set distance from the end fitting to prevent the bend stiffener from sliding along the flexible line simplifying the recovery and pull in process

- In service Freak loads unforeseen by global analysis or metocean data can lead to damage and the stiffener becoming detached. The clamp can be fitted prior to deployment or retrospectively to prevent a damaged stiffener being lost at sea or adversely affecting the performance of the flexible at an undesired location

Using the design parameters of the flexible line the same clamping performance as the DBM clamp range provides confidence that the bend stiffener will not travel further than desired should damage and potential failure occur.