ARE YOU SEEKING SURETY IN RISER PROTECTION DESIGN, MANUFACTURE AND DELIVERY?

Established in 1980, Balmoral has an enviable reputation across the world for product design, development and delivery.

With 500+ people based at our purpose-built 250,000ft2 facility in Aberdeen, we build successful relationships with clients working with them from concept development and advice through to product design, manufacture, testing, delivery and support.

All managed in-house to give total safety, quality and scheduling control.

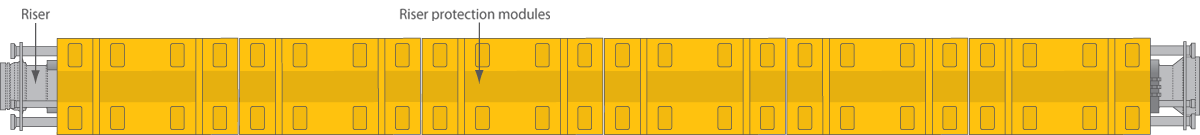

RISER PROTECTION SOLUTIONS

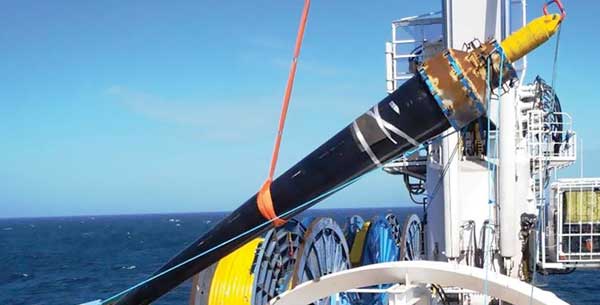

The Balmoral riser impact protection system allows the bare joint to be stored in the same stack as buoyant riser joints and minimises the chance of operational damage during deployment and recovery.

When running a bare riser string, ie, without buoyancy modules, several problems can be encountered on the drill platform including:

- Storage difficulties because of the differences and irregularities in profile

- Impact damage while being passed through the rotary table

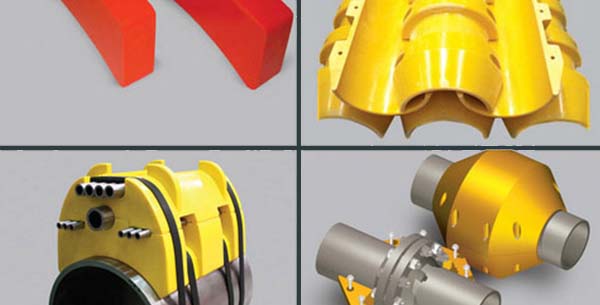

To minimise damage during operations Balmoral provides a selection of riser impact protection systems:

- Rotationally moulded polyethylene modules for standard protection

- A combination of polyethylene and polyurethane elastomer modules for heavy duty protection and maximum stacking

These products are engineered to provide maximum impact and abrasion protection whilst at the same time being lightweight and easy to handle.

Balmoral riser protection modules are fitted around the riser with moulded apertures accommodating auxiliary lines and riser clamps.