BUOYANCY > MOORING / INSTALLATION BUOYANCY

Mooring / installation buoyancy

Surface, subsurface buoyancy and in-line mooring systems

The offshore industry’s go-to buoyancy solutions

Our comprehensive range of surface and subsurface buoys spans from anchor pendant, mooring, one-piece and tri-buoys, to our bespoke in-line mooring systems, which can be used in conventional energy or floating offshore wind projects.

For us, no two projects are alike, and we work collaboratively to meet your project buoyancy needs quickly, safely and cost-effectively whether configured from our standard range or drawing on our bespoke engineered solutions.

Whether they will be in the water for the duration of project installation, or in-situ for 25 years, Balmoral Comtec offers the industry’s trusted, go-to buoyancy solutions.

Buoyancy manufacturing excellence

Mooring and installation buoyancy innovations

Balmoral offers a bespoke in-line mooring system which provides several unique characteristics and advantages.

Balmoral in-line mooring buoyancy uses a proprietary connection system as an integral part of the central steel work. Buoyancy mounted on either side of the connection system means the key interface is at the centre of the assembly. This minimises movement, isolates buoyancy from any load transfer, reduces fatigue, and provides an all-round stable solution.

The buoyancy elements can be offered from our standard modular range or, for more specific solutions, bespoke buoyancy elements can be manufactured to suit.

Key features and benefits:

- All mooring loads are transferred through the proprietary connection system

- Increased stability as the mooring loads pass through the centre of gravity

- No wearing parts in the buoyancy structure

- Enhanced fatigue resistance

The Balmoral mooring buoy range is unique and was designed and developed in-house.

Two forms of standard mooring buoys are available, ie, cylindrical and rectangular in section.

Specials are available and are usually based on a standard modular construction incorporating platforms, ladders, solar panels, electronic monitoring and lighting equipment.

Anchor pendant buoys are typically constructed from a rigid polyurethane foam core, cast around a central steel tension member that is reinforced with a glass reinforced polyester skin. The buoys are clad in a resilient polyethylene layer which is externally coated with a tough abrasion resistant polyurethane elastomer skin.

These units are suitable for deployment over the stern roller of anchor handling vessels.

APB |

Weight in air | Nominal buoyancy |

|---|---|---|

APB1 |

310 Kg | 1000 Kg |

APB2 |

560 Kg | 2000 Kg |

APB4 |

1160 Kg | 4000 Kg |

APB6 |

1330 Kg | 6000 Kg | APB8 |

1580 Kg | 8000 Kg | APB10 |

1770 Kg | 10000 Kg | APB15 |

2360 Kg | 15000 Kg | APB20 |

2860 Kg | 20000 Kg |

Note: All weight in air and buoyancy values are nominal and subject to specific configuration.

Balmoral’s design team created the Balmoral OCEANUS® float to provide a range of standard, readily available, buoyancy units suitable for all ocean depths.

Oceanus floats comprise a high performance low density composite foam buoyancy core, encapsulated within a tough impact and abrasion resistant polyethylene shell and are supplied in a variety of colours with moulded-in client graphics where required.

To simplify the handling of Oceanus floats during deployment and recovery, each Oceanus features a pair of recessed lifting holes sized to accommodate ‘gloved hands’. The floats also incorporate a series of flat surfaces to assist on-board stability and facilitate close grouping as part of operation or storage.

The standard range of Oceanus floats covers four uplift capacities and six standard operating depths.

Oceanus float values

Weight in air (kg) - Nominal buoyancy (kg)

| Operating depth (msw) | OF1 | OF2 | OF3 | OF4 |

|---|---|---|---|---|

| 1000 | 7.9 - 7.7 | 11.9 - 12.2 | 21.2 - 23.2 | 43.8 - 50.4 |

| 1500 | 8.1 - 7.5 | 12.3 - 11.8 | 22 - 22.4 | 45.6 - 48.6 |

| 2000 | 8.9 - 6.7 | 13.4 - 10.6 | 24.2 - 20.2 | 50.4 - 43.8 |

| 2500 | 9.2 - 6.4 | 14 - 10 | 25.4 - 19 | 53.1 - 41.1 |

| 3000 | 9.8 - 5.8 | 14.9 - 9.2 | 27 - 17.4 | 56.6 - 37.6 |

| 6000 | 10.6 - 5 | 16.2 - 7.9 | 29.6 - 14.8 | 62.3 - 31.9 |

| Bore ØID | 19.05mm | 38.1mm | 38.1mm | 38.1mm |

Note: All weight in air and buoyancy values are nominal and subject to specific configuration.

Tri-buoys offer a simple cost effective solution where additional buoyancy may be required as part of an installation operation or small permanent mooring.

The tri-buoys are finished either in GRP or elastomer and are supplied with central steelwork bearing a pad eye and swivel at either end. If required a smooth central bore can be created to enable the use of a mooring rope.

Balmoral tri-buoys provide a buoyancy uplift of between 125-175kg with depth rating capabilities of 610-3050msw.

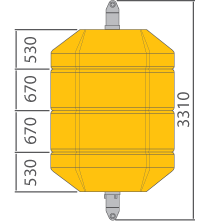

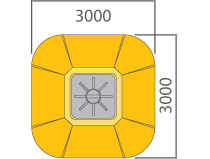

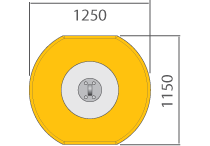

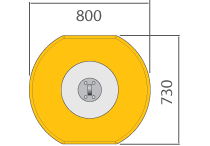

Designed for use from 0-3000msw these buoys are used predominantly as suspended moorings or subsea markers. Balmoral modular buoyancy is highly adaptable and can be fitted with a comprehensive range of end fittings.

Balmoral’s modular buoyancy utilises a range of tough, abrasion resistant core materials contained within a rotational moulded polyethylene shell. Other external finishes are available on request.

Balmoral MB60 modular buoys are available in sizes ranging from 100-300 tonnes.

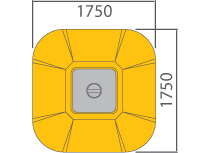

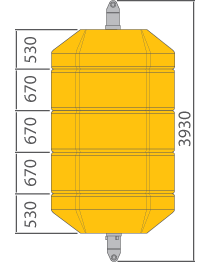

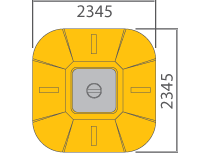

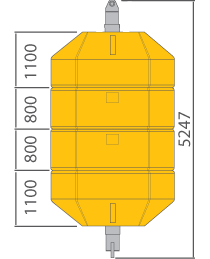

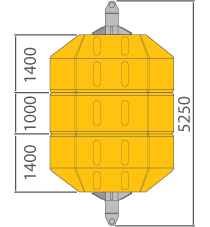

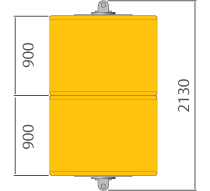

MB17 general arrangements

Weight in air (kg) - Nominal buoyancy (kg)

|

Surface | 300 msw | 500 msw | 1000 msw | 1500 msw | 2000 msw |

|---|---|---|---|---|---|---|

|

708 - 1695 | 1333 - 1070 | 1405 - 999 | 1422 - 912 | 1520 - 815 | 1634 - 701 |

|

975 - 3279 | 2104 - 2149 | 2233 - 2021 | 2270 - 1880 | 2447 - 1703 | 2653 - 1497 |

|

1241 - 4863 | 2875 - 3229 | 3061 - 3042 | 3118 - 2848 | 3374 - 2592 | 4301 - 3481 |

|

1507 - 6447 | 3646 - 4308 | 3890 - 4064 | 3966 - 3815 | 4301 - 3481 | 4691 - 3091 |

Buoyancy values can be increased by approximately 0.4 - 0.75 tonnes per configuration with the addition of a thin mid module

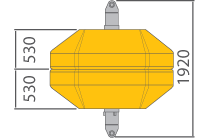

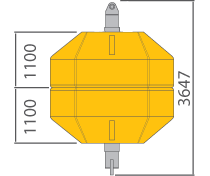

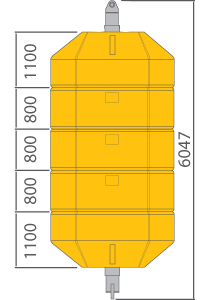

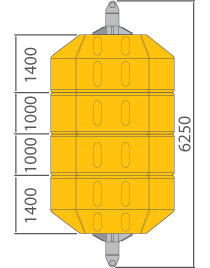

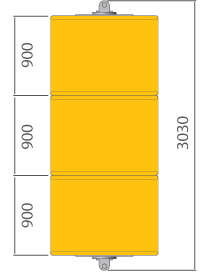

MB23 general arrangements

Weight in air (kg) - Nominal buoyancy (kg)

|

Surface | 300 msw | 500 msw | 1000 msw | 1500 msw | 2000 msw |

|---|---|---|---|---|---|---|

|

1645 - 7061 | 4033 - 4673 | 4305 - 4401 | 4394 - 4165 | 4767 - 3792 | 5203 - 3356 |

|

2179 - 10597 | 5693 - 7083 | 6094 - 6683 | 6227 - 6392 | 6776 - 5813 | 7417 - 5172 |

|

2714 - 14134 | 7354 - 9494 | 7883 - 8965 | 8060 - 8559 | 8785 - 7834 | 9632 - 6987 |

|

3249 - 17670 | 9014 - 11905 | 9672 - 11247 | 9893 - 10756 | 10794 - 9855 | 11846 - 8803 |

Buoyancy values can be increased by approximately 0.75 - 1.5 tonnes per configuration with the addition of a thin mid module

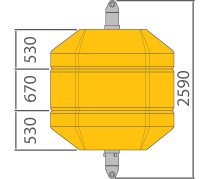

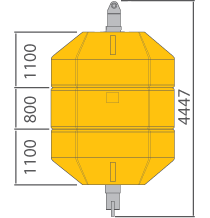

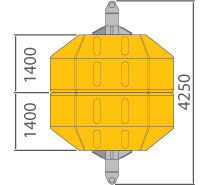

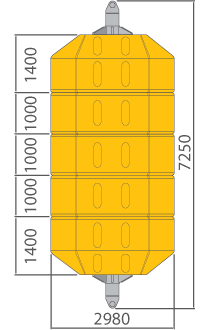

MB30 general arrangements

Weight in air (kg) - Nominal buoyancy (kg)

|

Surface | 300 msw | 500 msw | 1000 msw | 1500 msw | 2000 msw |

|---|---|---|---|---|---|---|

|

3457 - 16254 | 8915 - 10796 | 9537 - 10174 | 9729 - 9529 | 10582 - 8676 | 11578 - 7680 |

|

4518 - 23763 | 12348 - 15907 | 13271 - 15011 | 13557 - 14160 | 14785 - 12932 | 16218 - 11499 |

|

5579 - 31274 | 15836 - 21017 | 17005 - 19847 | 17385 - 18791 | 18988 - 17186 | 20860 - 15316 |

|

6640 - 38784 | 19296 - 26128 | 20739 - 24684 | 21213 - 23421 | 23192 - 21442 | 25500 - 19134 |

Buoyancy values can be increased by approximately 1.75 - 3.5 tonnes per configuration with the addition of a thin mid module

Note: All weight in air and buoyancy values are nominal and subject to specific configuration.

Balmoral has developed its range of modular subsurface buoyancy products to include standardised “off-the-shelf” solutions.

Designed to offer a cost effective and rapid response to immediate buoyancy requirements, the new buoys complement the company’s existing range of products suitable for use from 0-2000msw.

These modules incorporate ‘flats’ which provide easier handling and deck storage whilst simultaneously improving robustness.

We believe these are the most user-friendly subsurface buoys on the market.

CMB general arrangements

Weight in air (kg) - Nominal buoyancy (kg)

|

Surface | 300 msw | 500 msw | 1000 msw | 1500 msw | 2000 msw |

|---|---|---|---|---|---|---|

| 289 - 890 | 587 - 592 | 621 - 558 | 632 - 527 | 679 - 480 | 733 - 426 | |

|

376 - 1819 | 972 - 1223 | 1040 - 1156 | 1063 - 1094 | 1156 - 1000 | 1265 - 896 |

|

463 - 2749 | 1357 - 1855 | 1458 - 1753 | 1493 -1660 | 1633 - 1521 | 1796 - 1358 |

Note: All weight in air and buoyancy values are nominal and subject to specific configuration.

Designed to offer a cost effective and rapid response to immediate buoyancy requirements, mini cylindrical modular buoys complement the company’s existing range of products suitable for use from 0-2000msw.

These modules incorporate ‘flats’ which provide easier handling and deck storage whilst simultaneously improving robustness.

We believe these are the most user-friendly subsurface buoys on the market.

MCMB buoyancy modules

Weight in air (kg) - Nominal buoyancy (kg)

|

Surface | 300 msw | 500 msw | 1000 msw | 1500 msw | 2000 msw |

|---|---|---|---|---|---|---|

| MCMB1 |

99 - 77 | 130 - 46 | 133 - 43 | 135 - 38 | 139 - 34 | 145 - 28 |

| MCMB2 |

103 - 108 | 144 - 67 | 148 - 62 | 150 - 56 | 156 - 50 | 164 - 43 |

| MCMB3 |

109 - 158 | 167 - 101 | 173 - 95 | 175 - 87 | 184 - 78 | 195 - 67 |

| MCMB4 |

118 - 229 | 199 - 149 | 208 - 140 | 211 - 129 | 224 - 116 | 238 - 102 |

MCMB typical configurations

Weight in air (kg) - Nominal buoyancy (kg)

| Surface | 300 msw | 500 msw | 1000 msw | 1500 msw | 2000 msw | |

|---|---|---|---|---|---|---|

| MCMB5 MCMB1 + MCMB2 |

115 - 202 | 187 - 130 | 195 - 122 | 198 - 112 | 209 - 101 | 222 - 88 |

| MCMB6 MCMB2 + MCMB3  |

126 - 283 | 224 - 185 | 235 - 174 | 239 - 160 | 254 - 145 | 272 - 127 |

| MCMB7 MCMB1 + MCMB4  |

131 - 324 | 242 - 212 | 255 - 200 | 259 - 184 | 276 - 167 | 297 - 147 |

| MCMB8 MCMB2 + MCMB4  |

135 - 354 | 256 - 233 | 270 - 219 | 274 - 202 | 293 - 184 | 315 - 161 |

| MCMB9 MCMB3 + MCMB4  |

141 - 405 | 279 - 267 | 294 - 252 | 300 - 233 | 321 - 211 | 347 - 186 |

| MCMB10 MCMB4 + MCMB4  |

150 - 476 | 311 - 315 | 329 - 297 | 336 - 275 | 361 - 250 | 390 - 220 |

| MCMB11 MCMB2 + MCMB3 + MCMB4  |

157 - 530 | 336 - 351 | 356 - 331 | 363 - 306 | 391 - 278 | 424 - 246 |

| MCMB12 MCMB2 + MCMB4 + MCMB4  |

166 - 601 | 368 - 399 | 391 - 376 | 399 - 348 | 430 - 317 | 467 - 280 |

| MCMB13 MCMB4 + MCMB4 + MCMB4  |

182 - 723 | 423 - 481 | 451 - 454 | 460 - 421 | 498 - 383 | 542 - 339 |

Note: All weight in air and buoyancy values are nominal and subject to specific configuration.

Balmoral Comtec provides a range of one-piece subsurface buoys, suitable for service to 3000msw, which have a proven track record on subsea projects undertaken by marine installation contractors.

These products are manufactured using a central tension member encapsulated within a syntactic foam core of varying densities to suit the required depth rating.

External finishes include rotationally moulded polyethylene, polyurethane elastomer and glass reinforced vinyl-ester, giving a durable, abrasion resistant surface finish. The external surface is pigmented with a high visibility colour – typically yellow, white or orange – to assist with deployment and retrieval although other colours are available on request.

Balmoral provides a range of floats to suit most control umbilicals. These floats comprise a pair of symmetrical half shells which are profiled to permit the line to flex within its specified bend radius.

Each float is manufactured using a low density composite foam core covered in a high performance impact and abrasion resistant polyethylene shell.

Balmoral's umbilical floats are hinged using two stainless steel latches. The floats are designed to grip the umbilical by means of a natural rubber internal grommet.

Designed to suit umbilical diameters ranging from 25mm-50mm OD, the floats can be supplied to suit larger diameter umbilicals if required.

Umbilical float values

| Operating depth (msw) | Weight in air (Kg) | Nominal buoyancy (Kg) |

|---|---|---|

| 1000 | 14.7 | 15.2 |

| 1500 | 15.9 | 14 |

| 2000 | 17.3 | 12.6 |

| 2500 | 18.1 | 11.8 |

| 3000 | 19.1 | 10.8 |

Note: All weight in air and buoyancy values are nominal and subject to specific configuration.

Field-proven, tested and trusted

We have been the trusted partner for the offshore energy industry for more than 40 years. In that time, we have consistently demonstrated an exemplary track record for safety, and we firmly believe our products have the lowest failure rates in the sector. Customers know they can rely on our longstanding experts and field-proven solutions, based on best-in-class engineering, product testing, and installation.

Talk to our leadership team about your project today

Whatever your project needs, we can work together to deliver project certainty.