Press release - 29 Oct 2020

Balmoral FibreFlex™ cable protection system delivers unique benefits

At a time of renewed interest and heightened activity in the offshore wind sector developers are seeking technological innovation from the supply chain to assist in their efforts to maximise efficiency and minimise cost.

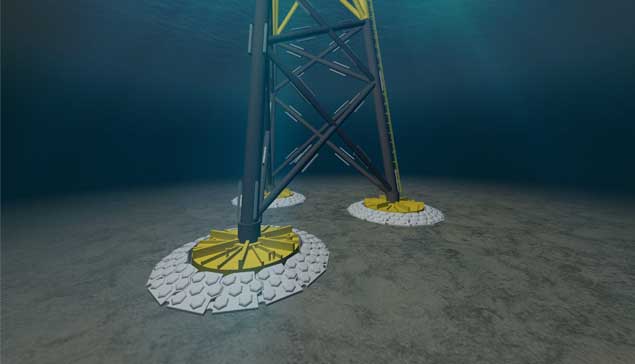

Much of the technology being used by the sector is derived from the traditional offshore energy arena, particularly where subsea-related product solutions are required and, with well documented cable failures eating up substantial resources, both in terms of cash and time, high performance cable protection systems (CPS) can play a key role in failure mitigation.

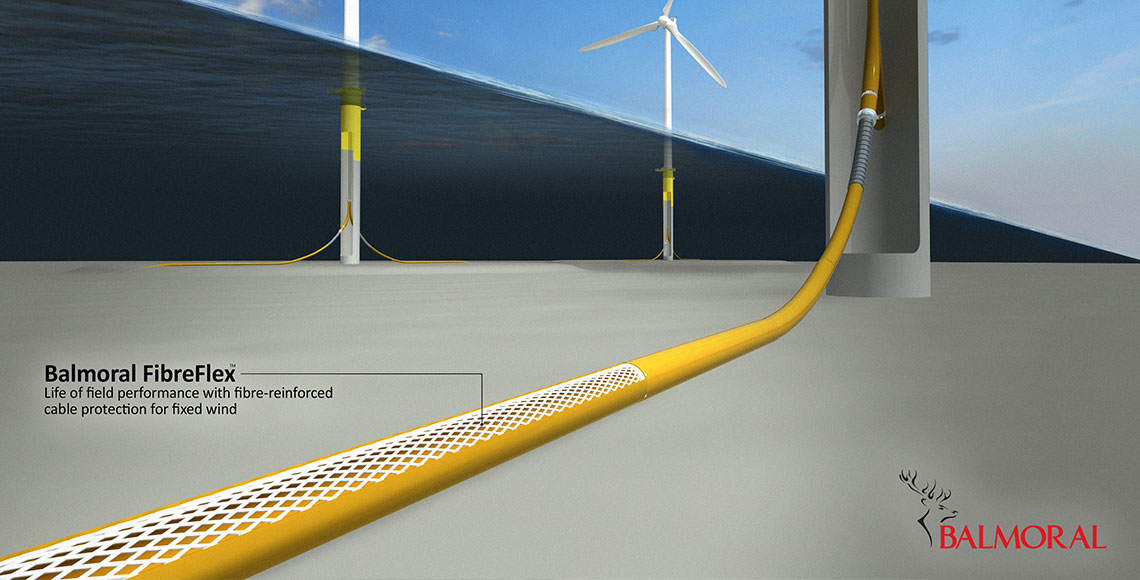

One company that has taken a different approach to offshore wind cable protection is Balmoral. Recognised for its experience in extreme subsea environments, the company has adapted its polyurethane design engineering and manufacturing capabilities to develop a high performing cost-efficient patented CPS solution: Balmoral FibreFlex™.

Our technical and engineering teams have created a unique solution that is designed to provide maximum performance for life of field installations

Fraser Milne is the company’s engineering and projects director and says: “Our technical and engineering teams have created a unique solution that is designed to provide maximum performance for life of field installations.”

The fibre-reinforced system mechanically locks to the end connectors removing the need to rely on PU bonding, which is notoriously unpredictable, while providing market-leading strain and stiffness levels that are unachievable using traditional solid PU manufacturing methods. These innovations also contribute to greatly increased fatigue life.

Milne continued: “Our system provides an increase in axial tension capacity by a factor of two while controlling axial elongation. It also increases bend stiffness by a factor of 1.5 allowing improved control and reduction in the cable’s maximum bend radius within a slimline profile.”

Balmoral says FibreFlex’s long-term creep performance is a substantial improvement on traditional cable protection while bending and axial stiffness is optimised without having to qualify alternative PU materials.

Ian Milne, sales manager for renewable products at Balmoral, said: “We are well known for our technical and engineering capabilities and our design team has created a unique system that can be deployed on most fixed wind developments.

“I believe Balmoral FibreFlex represents a huge step forward in cable protection offering improvements across installation, management and maintenance.

“We are seeing increased awareness and interest in the system which is already being used safely and successfully on a number of developments around the world.”

Balmoral’s 40-year track record of providing tried, tested and proven subsea protection products is set to benefit the global offshore wind sector with the company recently achieving the sought-after Fit 4 Offshore Renewables (F4OR) accreditation.