Innovating for a balanced offshore energy transition

At Balmoral Comtec, A Balmoral Group company, we don’t just adapt to change - we drive it. For more than four decades, we’ve been at the forefront of offshore energy innovation, delivering advanced composite materials for buoyancy, subsea protection and insulation. Our solutions are trusted across the globe, enabling the offshore energy sector to achieve its net zero goals while maintaining operational excellence.

What we do

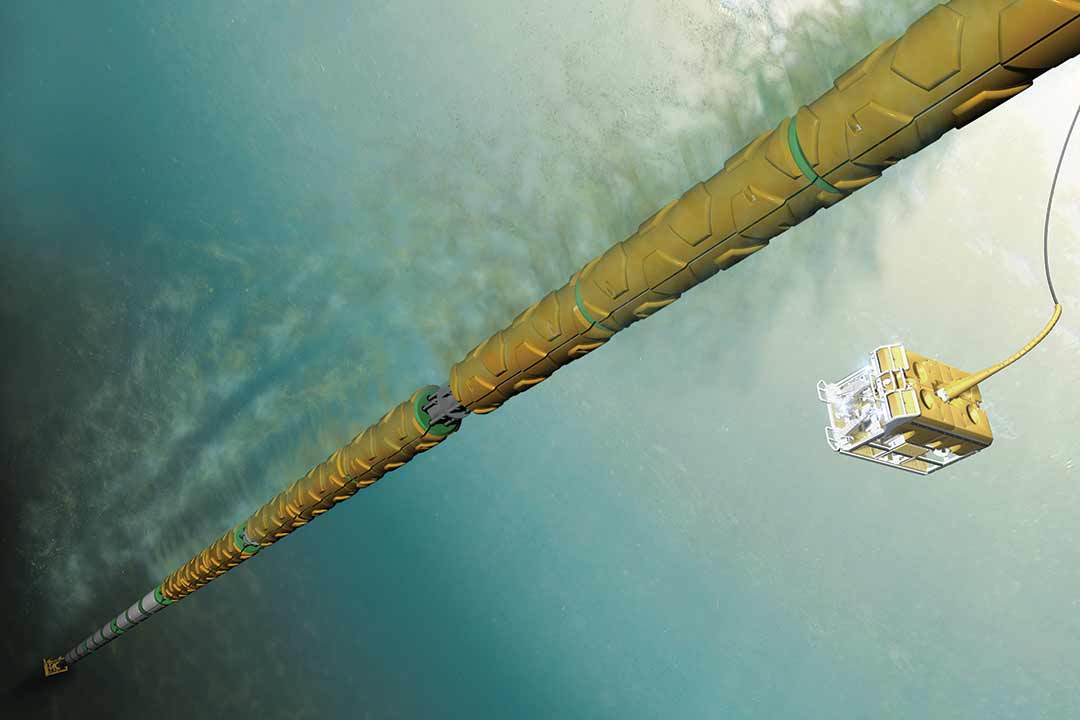

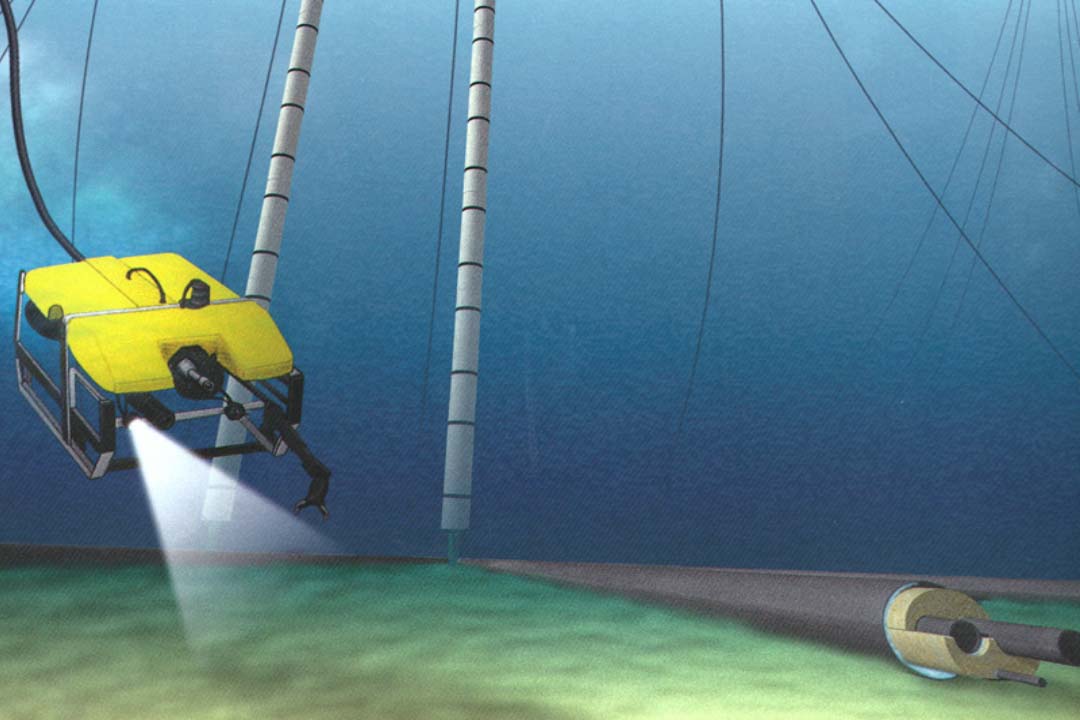

We solve complex engineering challenges with precision and care. From bend restrictors and stiffeners to cutting-edge cable and pipeline protection systems, our products are engineered to meet the unique demands of offshore environments. Whether safeguarding assets in harsh subsea conditions or pioneering sustainable energy innovations like HexDefence, we combine expertise with technology to deliver unmatched project certainty.

Problem solvers

We partner with our customers to solve their engineering challenges, ensuring the best total cost of ownership.

Trusted experts

With an unrivalled track record, our customers rely on our expertise and field-proven solutions.

Technological innovators

We continuously invest in research and development to stay at the forefront of innovation.

Equipped to deliver

Our state-of-the-art facilities and highly skilled teams enable us to deliver any project successfully, efficiently and safely.

Our people

Leadership team

Leadership is more than a title. It is a commitment, and our people are our greatest asset.

Awards and achievements

Excellence isn’t just a goal; it’s our standard. These accolades reflect our relentless drive to push boundaries and redefine what’s possible in offshore engineering.

Our history

Founded in 1980 by Sir James S. Milne, Balmoral Comtec emerged from Aberdeen’s thriving offshore sector. What began as a diversification from construction into energy has evolved into a global leader in subsea innovation. Over the decades, we’ve grown with the industry, anticipating its needs and delivering solutions that make history.

Discover our timeline of industry innovation...

2024

Balmoral Comtec marks renewables milestone with Hornsea 3 contract award for cable protection systems

2024

2024

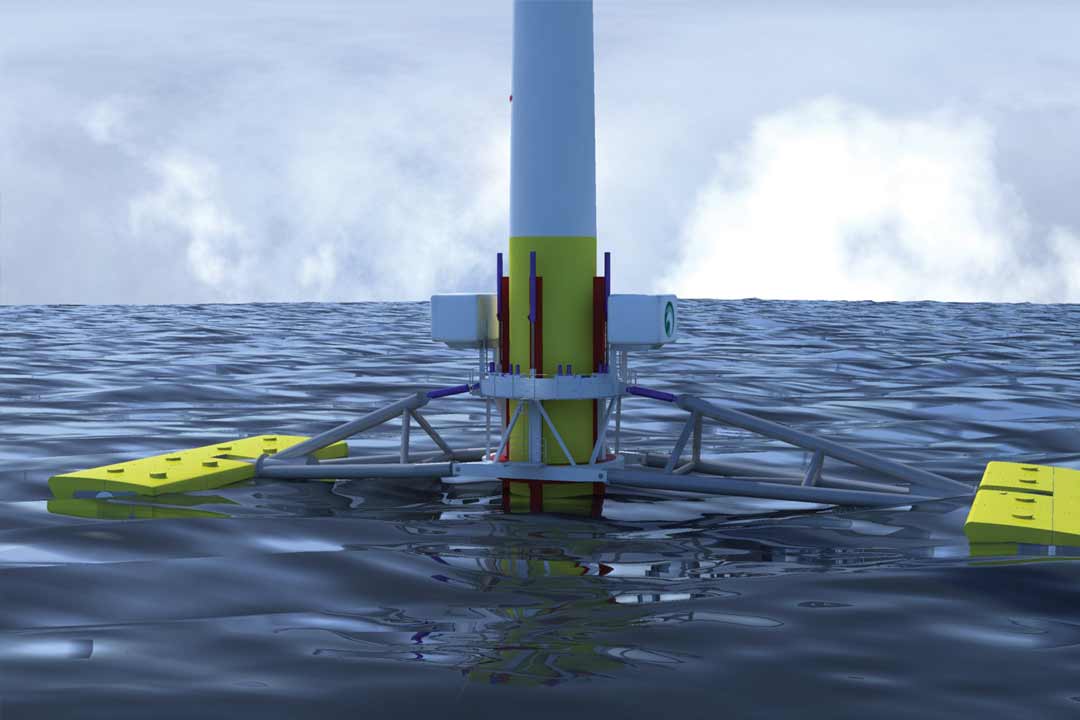

Balmoral HexDefence wins ‘Transformational Technology Award’ at Offshore Achievement Awards

2023

Innovative HexDefence scour protection launched for jacket and monopile foundations

2023

2023

Balmoral Comtec establishes itself as a pionerring supplier for the renewables sector

2020

Balmoral celebrates 40 years of industry innovation

2020

2019

Low density foams introduced for use 2000-7000msw

2018

Drill riser VIV suppression and drag reduction system lanuched

2018

2018

Balmoral Subsea Test Centre launched by Duke of Rothesay

2017

Undertake joint study to develop materials and processes for the production of wave energy converters for renewable industry

2017

2016

Construction of Balmoral Subsea Test Centre begins

2015

Third Queen’s Award for International Trade

2015

2015

Pioneering mooring system developed with Moorlink for Western Isles project

2014

Shell Stones, GoM, deepest distributed buoyancy project, 9500ft with safety factor x2

2014

2014

Hybrid riser tower insulation buoyancy supplied to CLOV development, offshore Angola

2013

Largest bend stiffeners 15m long by 3m root diameter

2013

2012

Deepest ever drill riser buoyancy launched, 15,000ft, Durafloat Superlite

2012

Second Queen’s Award for International Trade

2012

2011

Balmoral Brazil launched

2010

First Queen's Award for International Trade

2010

2008

890 distributed buoyancy modules supplied to Indian FPSO for the MA:D6 field development

2007

Jim Milne picks up three awards during a very busy year for Balmoral

2007

2007

DuraFloat drill riser buoyancy introduced

2006

Balmoral Hydrospace Test Centre opens, testing to 6000msw

2006

2001

Distributed buoyancy used on deepest ever project, Deepwater Spirit in GoM, 9687ft

2000

Export sales jump 60%+

2000

1999

Hybrid thermal buoyancy modules for Girassol, largest ever order to date $50m

1997

Opening of Balmoral Houston factory. Drill riser modules for Reading & Bates, Transocean

1997

1994

Tow buoys for Conoco Heidrun project, Norway

1993

Phase two of Balmoral Park initiated

This located Webco, Marine, R&D, GRP and Rotomoulding to Balmoral Park, Aberdeen

1993

1990

St Fergus pipeline insulation

1987

Largest ever buoyancy modules produced to date for Green Canyon project in GoM

1987

1986

Balmoral Norge founded

1983

ROV buoyancy for Oceaneering, SubSea Offshore and Santa Fe

1983

1981

Survival craft for Hyundai and Well & Lambie

1980

Early contracts

Early contracts were awarded by BP and Shell for GRP spar buoys.

1980

1980

Company founded by Sir Jim Milne CBE

A company proud of its heritage in the North-east of Scotland, Balmoral Group was established with four employees

Core values

At Balmoral Comtec, our values guide everything we do. From our Aberdeen headquarters to projects spanning the globe, we remain steadfast in our mission: to balance reliable conventional energy operations with the acceleration of renewable and low-carbon solutions.

Customer focus

Leading and working together as a team to deliver high quality products on time at the best possible price with no surprises

Respect

Treating clients and colleagues as we wish to be treated ourselves, with respect and decency

Integrity

Reliability, flexibility, honesty, openness and fairness. Supporting clients and colleagues at all times with a focus on the common end goal

Accountability

Being proactive in setting and achieving objectives. Taking responsibility in one’s role and enhancing the company reputation at all times

Innovation

A commitment to the company’s philosophy of innovation, continuous improvement and clear communication, internally and externally

Motivation

Maintaining a focus on aligning efforts and energy to achieve common goals, ie, successful projects. Constantly seeking to add value

Talk to our leadership team about your project today

Whatever your buoyancy project needs, we can work together to deliver project certainty.