Press release - 3 May 2022

New Balmoral buoyancy and wind solutions on display at OTC

Aberdeen-based buoyancy, protection and insulation specialist, Balmoral, returned to OTC this week following the enforced two-year hiatus caused by the global pandemic.

The company’s presence on the UK Pavilion represents a run of continuous attendance at the event since the early 1980’s when chairman and managing director Jim Milne spearheaded Balmoral’s entry to the North American market.

Representatives from the technical and commercial teams are on the stand demonstrating the company’s latest developments in buoyancy, insulation and protection products as well as promoting FibreFlex™, a proprietary offshore wind cable protection system.

New buoyancy clamping system offers added value

In 2021 Balmoral launched a patented buoyancy clamping system that removes the need for separate clamping devices by attaching directly onto flexible flowlines, rigid pipelines, umbilicals, risers, etc.

The new system provides reduced and evenly distributed line contact through customised pads that accommodate expansion and contraction while generating consistent clamping loads.

Fraser Milne, engineering and projects director, told us from the Balmoral stand: “We believe the new system, Type Approved to API 17L standards, could be used on a minimum of 80% of distributed buoyancy requirements where a separate clamp solution would traditionally have been specified.

“Significant savings will be realised by a reduction in shipping costs, deck space requirements and product installation times.”

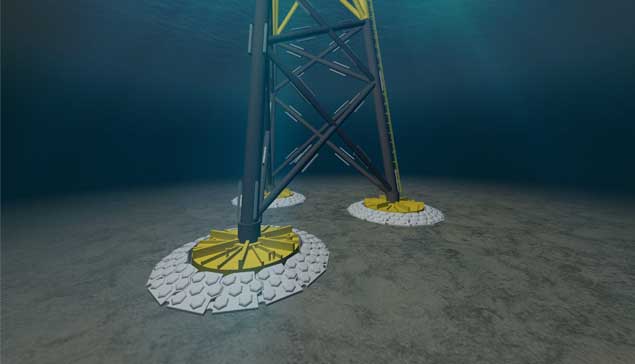

Optimised load distribution system with built-in clamp

Mitigating cable failure in offshore wind installations

A major talking point of 2021 for the offshore wind sector was cable failure with a contributing factor to this being a phenomenon known as scour development or erosion.

A unique system, designed to mitigate creep, is Balmoral’s patented FibreFlex™ cable protection technology that utilises a novel composite of polyurethane and polyester fibres that effectively creates a braided hose style system for the protection of subsea power cables.

Sales director, Gary Yeoman, is promoting the system at OTC for the first time and said: “It’s clear that the energy industry transition is gathering momentum this side of the Atlantic and it’s encouraging to see OTC embracing the move towards a low carbon energy future.

“FibreFlex is a game changing technology that takes advantage of the polymer’s highly elastic behaviour, its long-term subsea durability, excellent abrasion and impact properties, and combines them with the mechanical strength properties of the fibre.

“The initiative was inspired by engagement with clients, understanding the commercial aspect of not just field development but the longevity of the product, improving field reliability and therefore directly affecting the Level Cost of Energy (LCoE).

“Complemented by our buoyancy solutions that are used in floating wind installations we see exciting opportunities in this rapidly developing industry.”

Life of field performance with fibre-reinforced cable protection for fixed wind

Quayside facility investment for advanced composites fabrication

The company also reports a seven-figure investment in creating an advanced composites manufacturing facility at Montrose Port, south of Aberdeen, where large scale components for the offshore energy sector will be built.

Bill Main, managing director of Balmoral Comtec, also speaking from the stand, said: “We are building on our experience of working with the offshore wind sector and the new facility will allow us to fabricate and deliver very large composites structures direct from shore to ship.”